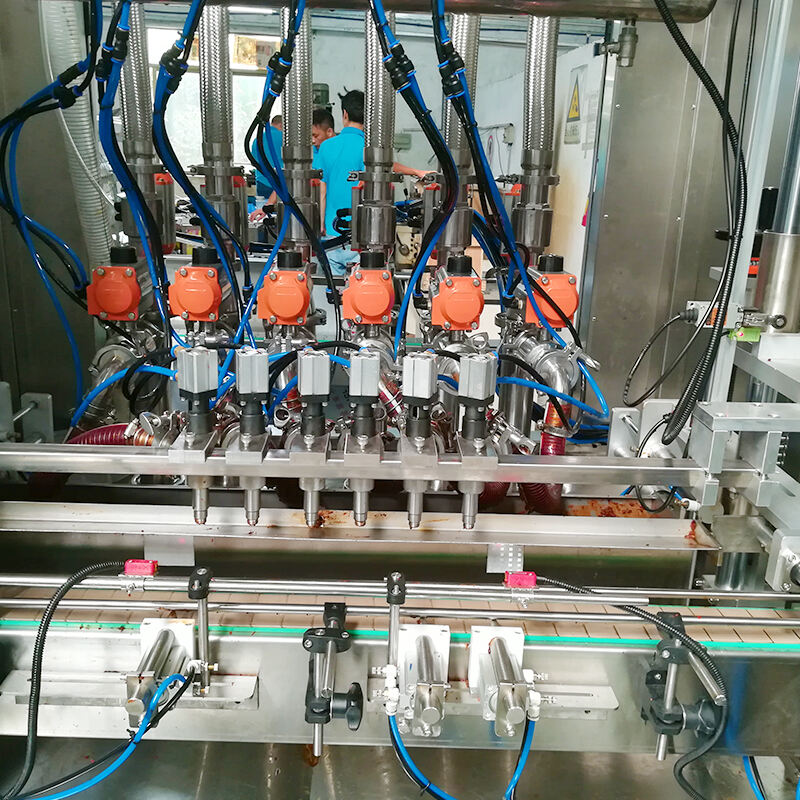

china sealer packaging

China sealer packaging represents the forefront of packaging technology designed to secure and preserve a wide range of products. The main functions of this innovative packaging solution include sealing various types of packaging materials to ensure product freshness, prevent contamination, and extend shelf life. Technological features of China sealer packaging are unparalleled, boasting precision engineering, programmable settings, and high-speed operation capabilities that cater to diverse industrial demands. These sealers are equipped with advanced control systems that allow for customization based on the specific needs of the product being packaged. Whether it's for food, pharmaceuticals, or industrial components, the applications of China sealer packaging are vast and critical to maintaining product integrity during storage and transport.