labeler labeler

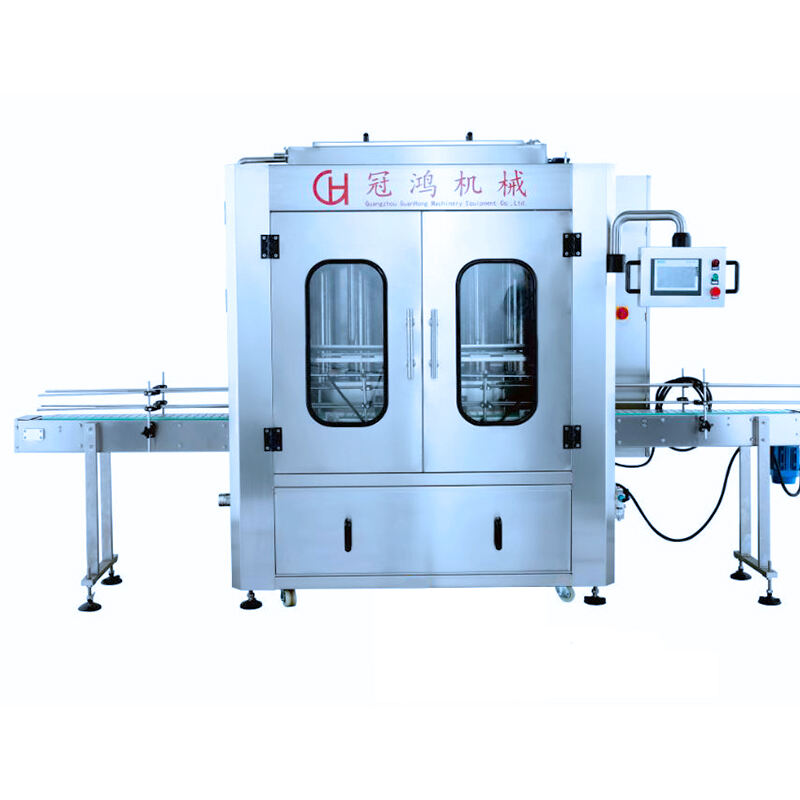

The labeler labeler is a state-of-the-art machine designed for efficient and accurate labeling of products. Its main functions include applying labels to a variety of packaging materials, such as bottles, cans, and boxes. Technological features of the labeler labeler include a user-friendly touchscreen interface, high precision label placement, and compatibility with a wide range of label sizes and types. This versatile equipment is ideal for industries such as food and beverage, pharmaceuticals, cosmetics, and more, where product labeling is crucial for branding, identification, and regulatory compliance. With its advanced features and reliability, the labeler labeler streamlines the packaging process, ensuring products are labeled correctly and efficiently, ultimately enhancing the overall productivity of the manufacturing line.