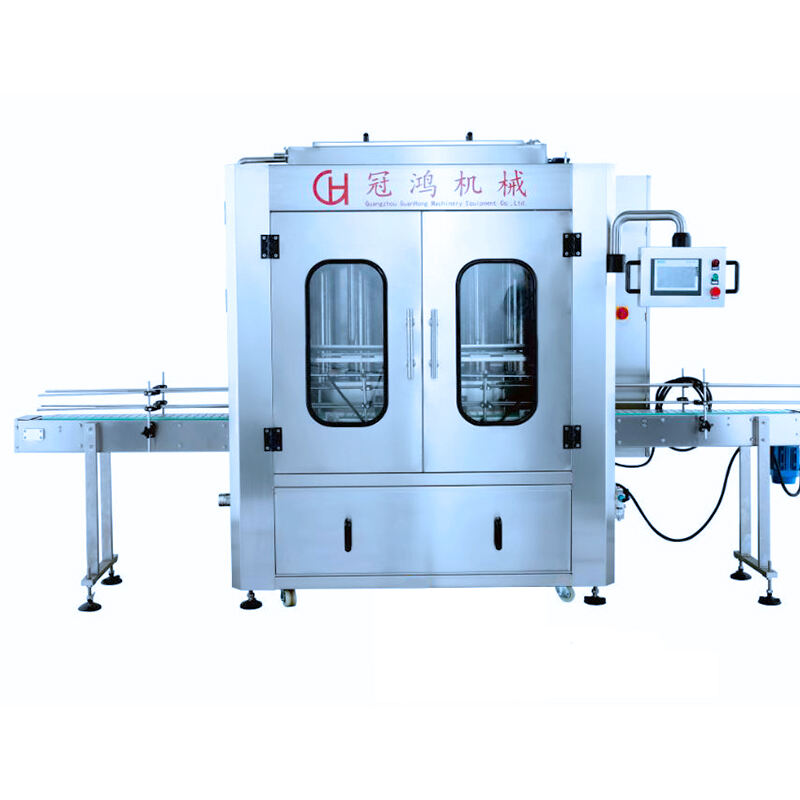

liquid filling machine supplier

The liquid filling machine supplier is a leading provider of state-of-the-art liquid packaging solutions. Their machines are designed for precision and efficiency, equipped with advanced technological features that cater to a wide range of industries. The main functions of these liquid filling machines include accurate volume measurement, consistent filling, and sealing, all of which are crucial for maintaining product integrity. With programmable settings, they offer versatile use for different liquid viscosities and container sizes. The machines are constructed with high-grade materials ensuring durability and easy maintenance. Whether it's for pharmaceuticals, food and beverages, cosmetics, or chemicals, these filling machines provide reliable performance in various applications.