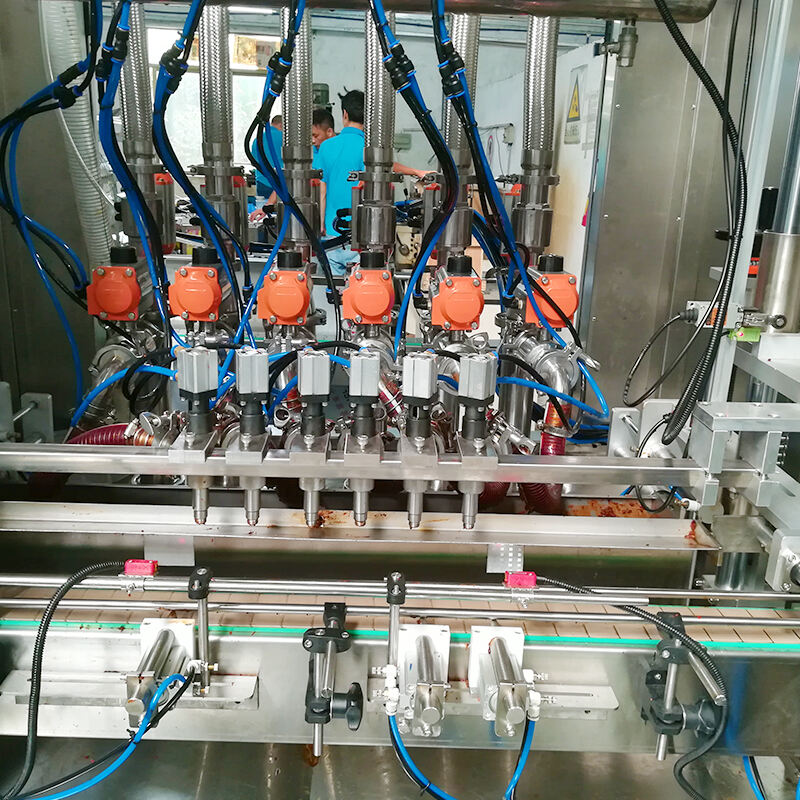

water pouch filling machine

The water pouch filling machine is a sophisticated piece of equipment designed to automate the filling and sealing of water into convenient pouches. Its main functions include precise water measurement, high-speed filling, efficient sealing, and automated output. Technological features include a state-of-the-art control system that ensures accuracy and consistency in pouch volume, a hygienic design that prevents contamination, and programmable settings for various pouch sizes. This machine is widely used in the beverage industry for packaging drinking water, as well as in pharmaceuticals and cosmetics for liquid products. It offers a reliable and efficient solution for businesses looking to enhance productivity and maintain high-quality standards in their packaging processes.