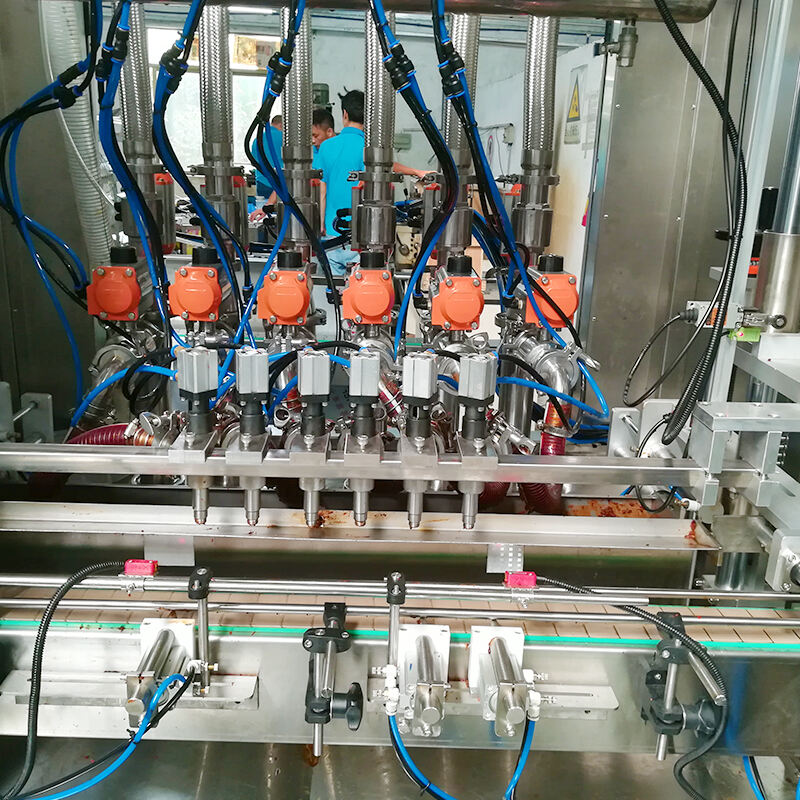

liquid soap filling machine

The liquid soap filling machine is a state-of-the-art piece of equipment designed to automate the packaging process of liquid soaps. It is equipped with advanced features that ensure precision and efficiency. The main functions of the machine include filling, sealing, and labeling containers of various sizes. Technological features such as a programmable logic controller (PLC) and a touch screen interface make the machine user-friendly and adaptable to different production needs. It utilizes a precision pump for accurate volume measurements and has an automatic nozzles cleaning system to prevent cross-contamination. This machine is ideal for industries such as personal care, pharmaceuticals, and household cleaning products, where high-speed and reliable liquid packaging is essential.